Today we also think about tomorrow

Thinking of the environment from raw material to consumption.

The 6 areas of our sustainable action

1. CO2 Emissions

We use energy sparingly and contribute to the "1.5 degree" target.

2. Water

We continuously use less water per metric ton of finished product.

3. Ecosystems

We act mindfully in our supply chains. We support biodiversity, particularly with organic raw materials and fair trade projects.

4. Healthy nutrition

As part of the "Pure Taste" strategy, we promote natural ingredients and sustainable nutritional offerings.

5. Packaging / Waste

We are increasing the proportion of recyclable packaging - together with our retail partners.

6. Conditions of employment

Our employees experience "sustainability" in their everyday lives - and are committed to it.

Regional, whenever

possible

We select raw materials very carefully with our suppliers.

Best raw materials for best taste

Our wide range includes products from conventional and organic cultivation. Together with our suppliers, we carefully select our raw materials and make sure that they are grown as regionally as possible. Nevertheless, there are some raw materials that do not grow in Europe. We therefore leave the cultivation and harvesting to specialists from Asia and Africa and make sure that the transport routes and means of transport are environmentally friendly. Selected, high-quality raw materials are the basis of convincing products. That's why we trust our long-standing and reliable suppliers in this area, who - just like us - are committed to maintaining a high standard of quality. For this reason, our raw materials and products are subject to constant quality controls.

RSPO

To promote sustainable agriculture, we are a member of the Round Table on Sustainable Palm Oil, RSPO for short. This is a central organisation that promotes sustainable cultivation methods in order to limit environmental damage. For us, it is clear that we use 100% sustainable palm oil.

Fairtrade

Fair partnership at eye level - with this approach our products taste much better. That's why we use fair trade cocoa in the production of our food service brand Vogeley.

Organic

As one of the pioneers and market leaders in the organic food segment, we have many years of development expertise. With our constantly growing organic range, we are committed to healthy soils, species-appropriate animal husbandry and resource conservation, while helping to reduce the use of pesticides and genetic engineering.

The path to sustainable packaging

Sustainable packaging protects our products from spoilage or damage and is made of environmentally friendly materials.

Reduce

We reduce the use of packaging materials wherever possible.

We have already reduced the use of plastic by 15% in our cup dishes and by 5-10% in our gastro buckets.

Reuse

We use packaging materials that are suitable for reuse, while using as much recycled material as possible.

Our gastronorm bowls and roll buckets in the food service area are reusable and hygienic to handle. Our fond jars can be reused, for example, for preserving jams.

Recycle

We use packaging materials that are suitable for reuse, while using as much recycled material as possible.

The jars of our broths can be easily separated into the individual components and can thus be assigned to the correct recycling stream.

Less energy, less CO2, less water

Optimising our consumption of resources is a continuous process.

We are constantly improving our eco-efficiency at our sites.

The careful use of resources is a central concern for us as a production company in order to conserve resources, save costs and care for the environment.

Our goal is therefore to reduce energy and water consumption and to use resources more efficiently, recycling them where possible or keeping them in as closed a loop as possible in order to contribute to the preservation of the environment.

Photovoltaics

Thanks to new installations of PV systems in 2023/2024, we can now use solar energy at all of our own production sites and are therefore partially self-sufficient in terms of electricity supply. We are also committed to the future and are expanding the areas for photovoltaics at the Radolfzell (DE) and Steinach (CH) sites.

Water

Water is particularly relevant for our tomato sauce production in Brivio (IT), where we were able to reduce the proportion of waste water per tonnage produced by 20% (2023 vs. 2022) by improving cleaning processes and raising employee awareness.

Heat recovery

Heat recovery from compressors saves around 41 tonnes of CO2 per year at our Zasmuky site. The plant also reduces around 124 tonnes of CO2 through the use of LED lighting.

Smart lightning

By using LED lighting at our site in Redditch, we can save around 50 tonnes of CO2 per year. You could drive a car around the world almost 9 times for that.

Climate-friendly enjoyment - our product range makes it possible

Our products contain many valuable ingredients such as delicious vegetables and herbs. After harvesting, these are gently dried on site and then transported to our production facility.

Our products are full of good ingredients and are also good for the environment

Our products contain many valuable ingredients such as delicious vegetables, herbs and spices. After harvesting, the ingredients are gently dried on site before they are transported to our production facilities.

Most of our products are also vegetarian and vegan.

In addition, the majority of our products are vegetarian and vegan. This means that the extraction of our raw materials carries a low CO2 footprint. For example, per 100 g of vegetable broth powder, the equivalent of about 18g of CO2 is emitted. By comparison, 100 g of butter emits around 238 g of CO2.

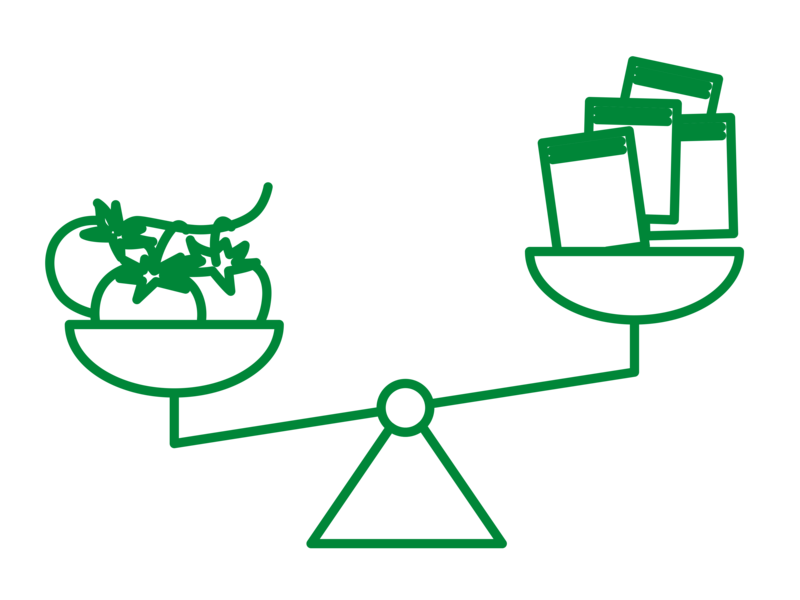

Less weight

Drying causes the raw materials to lose water and thus weight. The transport weight is greatly reduced and therefore causes less CO2. Thanks to the dried raw materials, our instant tomato soups are 8.5 times lighter than if we were to make them from fresh ingredients.

Less volume

Dried raw materials have a much smaller volume than fresh ones. For example, if 14 tonnes of tomatoes are transported in powder form instead of chunky, we can save a total of 10 truck journeys.

Less packaging material

Very often, dried foods reach the end customer with little packaging material. In addition, they do not have to be refrigerated during transport or on the sales shelf. This saves material and energy.